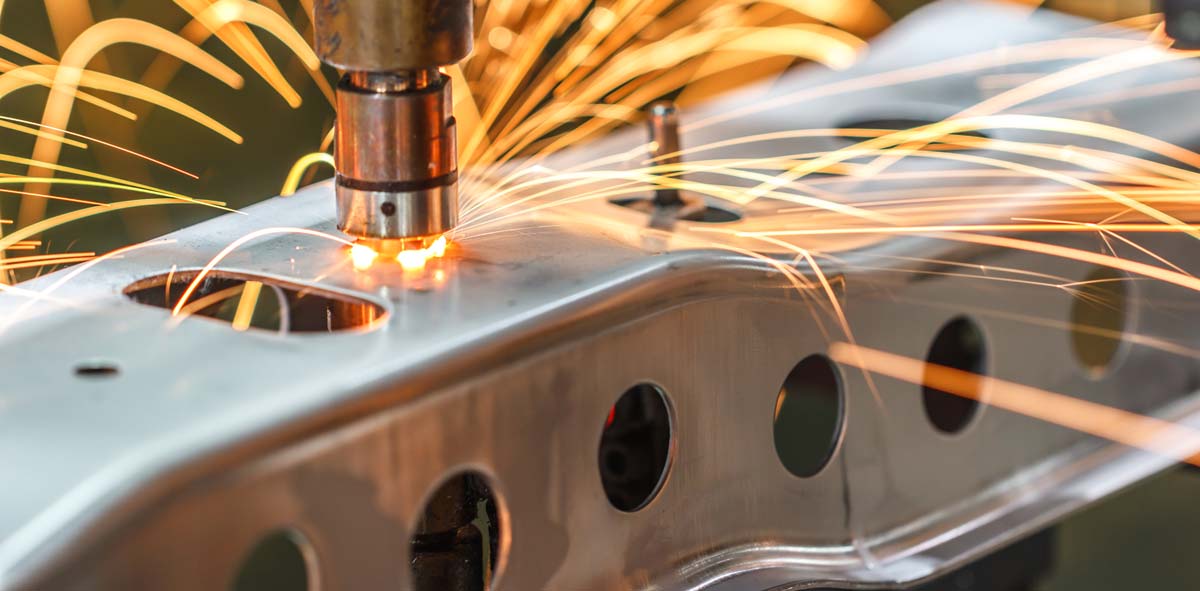

Precision Welding. Consistent Quality. Scalable Automation

Welding Automation uses robotic technology to deliver precise and repeatable Spot, MIG, and Arc welding for high-quality industrial manufacturing. Automated welding systems improve weld consistency, reduce cycle times, and enhance safety while supporting scalable, high-volume production with minimal human intervention.

Welding Automation integrates advanced industrial robots, intelligent welding systems, and precision control technologies to deliver high-quality, consistent, and repeatable welds across a wide range of manufacturing applications. By automating critical welding processes, manufacturers can significantly improve productivity, weld accuracy, and workplace safety while reducing dependency on manual labor. Robotic welding systems are widely used in automotive, heavy engineering, fabrication, and metal processing industries where precision and repeatability are essential.

Our welding automation solutions cover key welding processes including Spot Welding, MIG Welding, and Arc Welding. These systems ensure precise heat control, consistent weld penetration, and uniform joint quality while minimizing spatter and defects. Automated welding improves cycle times, reduces material waste, and delivers superior weld strength and aesthetics, making it ideal for both high-volume production and complex fabrication requirements.

Industry-leading robotic welding automation solutions delivering high precision, consistent weld quality, improved safety, and increased productivity for automotive, fabrication, and heavy engineering industries.

High-speed robotic spot welding solutions for automotive bodies, frames, and sheet metal assemblies, ensuring strong welds, repeatability, and reduced cycle time.

Automated MIG welding systems delivering smooth, uniform weld beads with deep penetration, ideal for metal structural steel fabrication and industrial welding applications.

Advanced robotic arc welding solutions providing precise heat control, arc stability, and superior weld quality for complex joints and heavy-duty components.