Collaborative Robot Automation

Safe and Efficient Collaborative Robot Automation for Modern Manufacturing

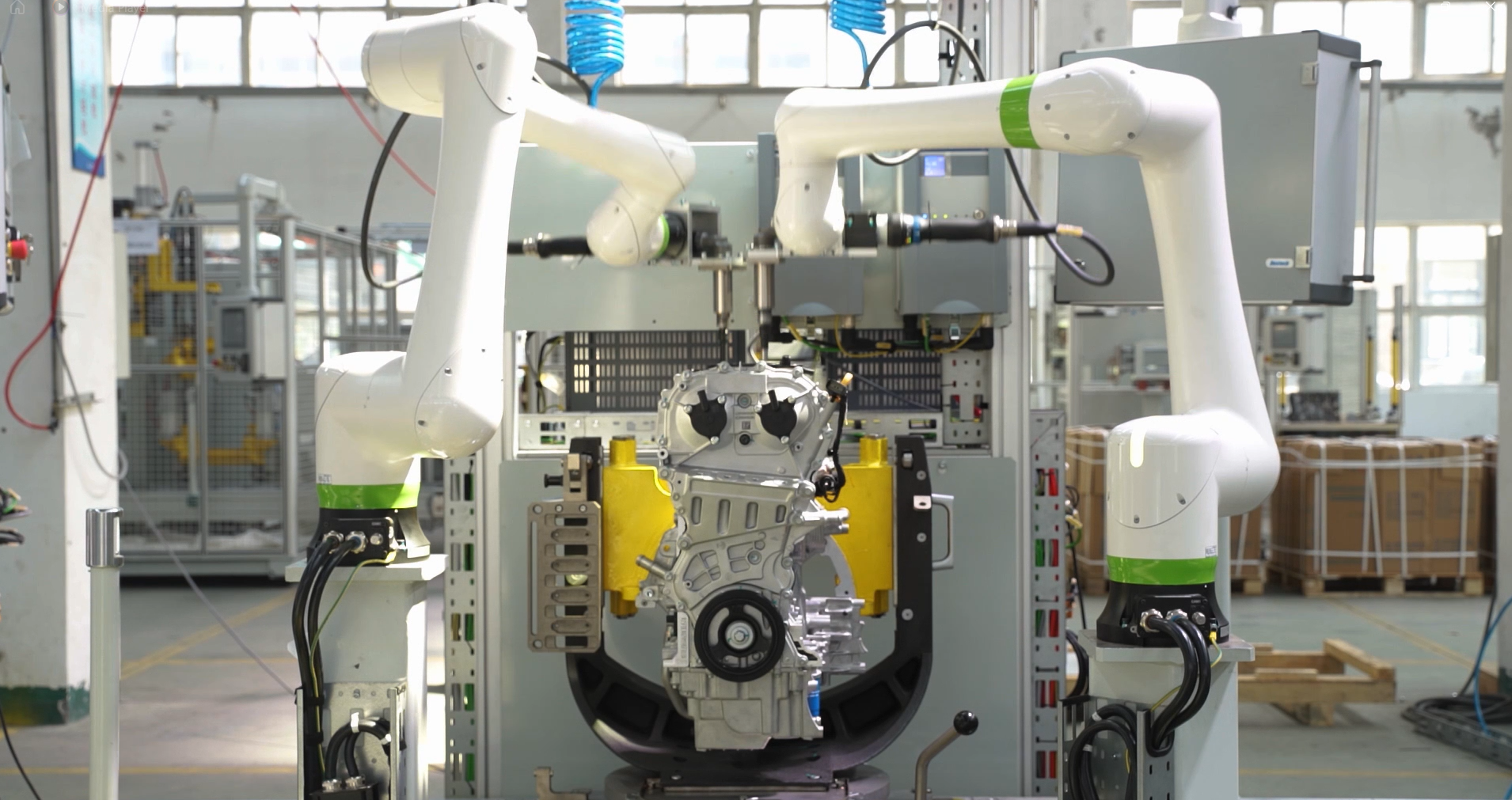

Collaborative robot automation brings safe, precise, and efficient solutions to modern manufacturing and industrial workflows. Our advanced robots work alongside human operators to handle assembly, material handling, and repetitive tasks, improving productivity, reducing errors, and ensuring consistent quality. Ideal for industries, 3D printing, and smart manufacturing environments seeking reliable, scalable automation.

Collaborative Robot Automation Overview

Collaborative robot automation utilizes intelligent cobots designed to safely operate alongside human workers within shared production environments. Unlike traditional industrial robots, collaborative robots are equipped with advanced safety technologies such as force sensing, speed monitoring, and collision detection, enabling direct human-robot interaction without the need for physical guarding. These systems are widely deployed for assembly, material handling, machine tending, inspection, and packaging applications requiring precision, flexibility, and efficiency.

Implementing collaborative robot automation enhances productivity, ensures consistent quality, and reduces manual workload across manufacturing operations. Cobots are easy to program, quick to deploy, and adaptable to changing production requirements, making them suitable for both low-volume and high-mix automation environments. By combining human intelligence with robotic accuracy, collaborative robot solutions deliver safe, scalable, and cost-effective automation across automotive, electronics, pharmaceuticals, food processing, 3D printing, and smart manufacturing industries.

Benefits

- Enables safe human–robot collaboration through integrated force sensing, speed monitoring, and collision detection

- Delivers high assembly precision and repeatability with accurate, controlled robotic motion

- Improves production efficiency by automating repetitive, time-intensive, and ergonomically challenging tasks

- Enhances workplace safety by reducing direct operator exposure to manual and high-risk operations

- Provides flexibility to adapt quickly to changing workflows, product variants, and production demands

- Minimizes errors and defects through precise control and consistent process execution

- Accelerates system deployment with intuitive programming and simplified integration into existing lines

- Optimizes workforce utilization by allowing operators to focus on higher-value and skill-based activities

- Supports scalable automation across assembly, material handling, inspection, and packaging applications

Collaborative Robot Automation Applications

System-integrated collaborative robot applications engineered to improve safety, precision, and operational efficiency across modern manufacturing environments.

Bin Picking & Pick and Place

Enables accurate bin picking and pick-and-place operations using vision-guided collaborative robots, ensuring reliable part handling, reduced cycle times, and consistent throughput.

Palletization & Depalletization

Automates palletizing and depalletizing processes with collaborative robots, improving end-of-line efficiency, reducing manual handling, and maintaining safe human-robot interaction.

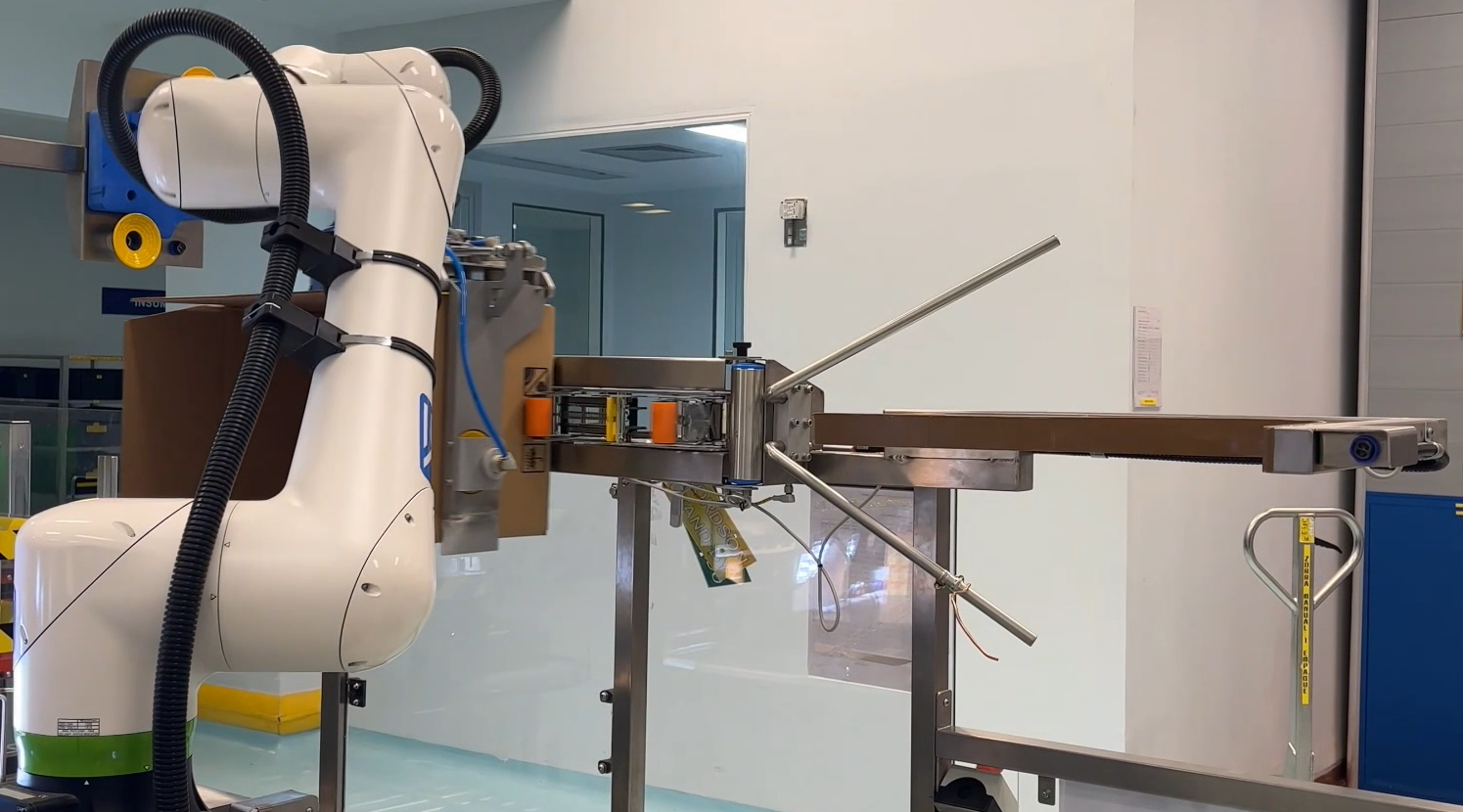

Machine Tending & Material Handling

Increases machine uptime by enabling collaborative robots to perform part loading, unloading, and material handling while operators focus on higher-value tasks.

Packaging & Sorting

Improves packaging and sorting operations through flexible, precise, and safe collaborative robot automation, supporting consistent quality and efficient order processing.