Assembly Automation

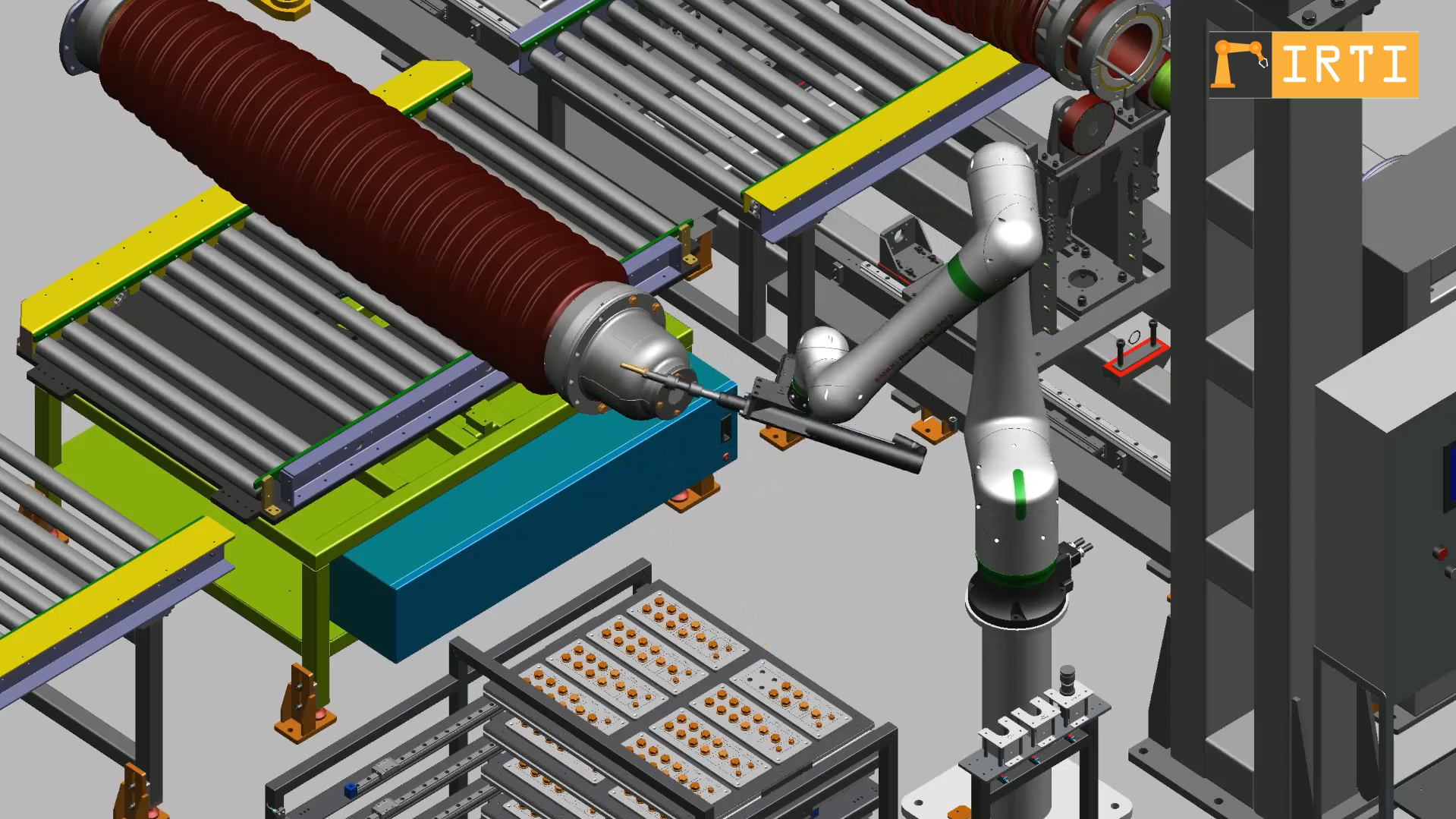

Engineered Assembly Automation for High-Accuracy, Scalable, and Reliable Manufacturing.

Assembly automation involves the engineering and system integration of industrial robots, smart tooling, vision inspection, and control architectures to execute precise assembly, fastening, insertion, and in-line quality verification operations. As a robotic system integrator, we design and deploy turnkey assembly automation solutions that reduce cycle time, ensure repeatable quality, improve operator safety, and enable flexible production scaling across automotive, electronics, appliance, and general industrial manufacturing environments.

Understanding Assembly Automation

Assembly automation involves the engineering and system integration of industrial robots, automated handling mechanisms, smart tooling, and intelligent control architectures to execute precision-driven assembly operations with high repeatability. These systems are designed to automate critical processes such as part handling, accurate positioning, fastening, joining, and in-line inspection, ensuring consistent quality while significantly reducing manual intervention. By integrating robots with vision systems, sensors, and force-feedback technologies, assembly automation enables reliable assembly of complex products across high-volume and high-mix manufacturing environments.

Engineered assembly automation solutions improve manufacturing efficiency by optimizing cycle times, eliminating process variability, and maintaining uniform assembly standards throughout the production line. These systems enhance workplace safety by removing operators from repetitive and ergonomically demanding tasks while enabling scalable, flexible production architectures. Widely deployed across automotive, electronics, appliance, and general industrial manufacturing, assembly automation systems deliver higher productivity, improved product quality, and long-term operational reliability essential for competitive industrial operations.

Benefits

- Ensures high-precision assembly with consistent accuracy across every production cycle

- Reduces cycle time and increases throughput with faster, automated assembly processes

- Improves product quality by minimizing human error and ensuring repeatable results

- Enhances workplace safety by eliminating repetitive, strenuous, and manual assembly tasks

- Supports flexible manufacturing for high-mix and high-volume production environments

- Integrates seamlessly with vision systems, sensors, and quality inspection tools

- Reduces operational costs through lower labor dependency and minimal rework

- Delivers reliable and scalable production with 24/7 continuous operation

- Improves traceability and quality control with automated data monitoring and reporting

Assembly Line Automation Solutions

SI-grade assembly line automation solutions engineered through the integration of industrial robots, smart tooling, vision systems, and line-level controls to deliver consistent quality, full traceability, and scalable production performance.

Robotic Pick & Place

Engineered robotic pick and place solutions for precise component handling, orientation, and placement, synchronized with upstream and downstream assembly processes for optimized cycle times.

Fastening & Torque Tightening

Automated screwdriving and torque-controlled fastening systems integrated with controllers and data logging to ensure process accuracy, traceability, and compliance in critical assembly operations.

Press-Fit & Joining

Robotic press-fit, snap-fit, and joining automation with force and displacement monitoring to ensure consistent assembly force, alignment, and repeatable joint quality.

Inspection & Quality Automation

Vision-based inspection and functional testing systems integrated inline with the assembly process to enable real-time quality verification, defect prevention, and zero-defect manufacturing.