Precision automation for safe, consistent, and high-performance press shop operations.

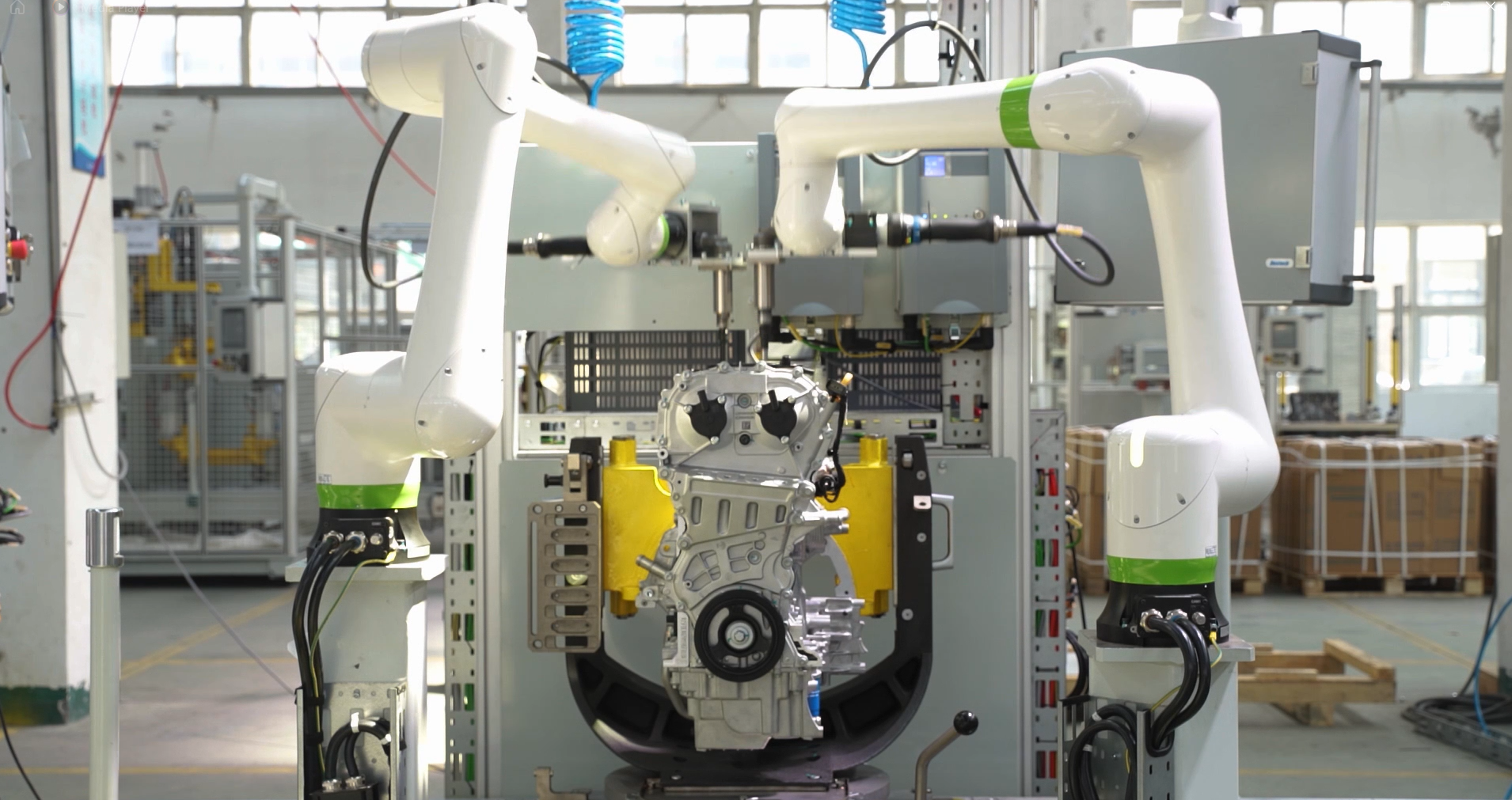

IRTI-Robotics delivers advanced robotic press shop automation solutions designed to enhance safety, accuracy, and productivity in sheet metal forming environments. Our systems automate critical press shop processes such as sheet metal blank loading, press-to-press part transfer, finished part unloading, scrap separation, and palletization. By integrating industrial robots, vision systems, and intelligent safety controls, we ensure consistent cycle times, improved quality, and reliable operation across single and tandem press lines.

Press shop automation refers to the use of industrial robots, automation systems, and intelligent controls to automate operations within a press shop environment. IRTI-Robotics delivers advanced press shop automation solutions for applications such as sheet metal handling, blank loading and unloading, press-to-press transfer, part orientation, and stacking. By integrating robotic handling systems, vision-guided automation, and safety interlocks, press shop automation improves production speed, ensures consistent cycle times, and reduces manual intervention in high-force manufacturing processes.

Designed for high-volume and heavy-duty operations, IRTI-Robotics’ press shop automation solutions enhance workplace safety, minimize downtime, and improve overall equipment effectiveness. Our systems support single-press and tandem press lines, enabling precise part transfer and reliable operation across varied component sizes and materials. From raw blank handling to finished part unloading, press shop automation helps manufacturers achieve higher productivity, improved quality consistency, and scalable metal forming operations.

Robotic automation solutions designed to improve safety, accuracy, and productivity across sheet metal press shop operations.

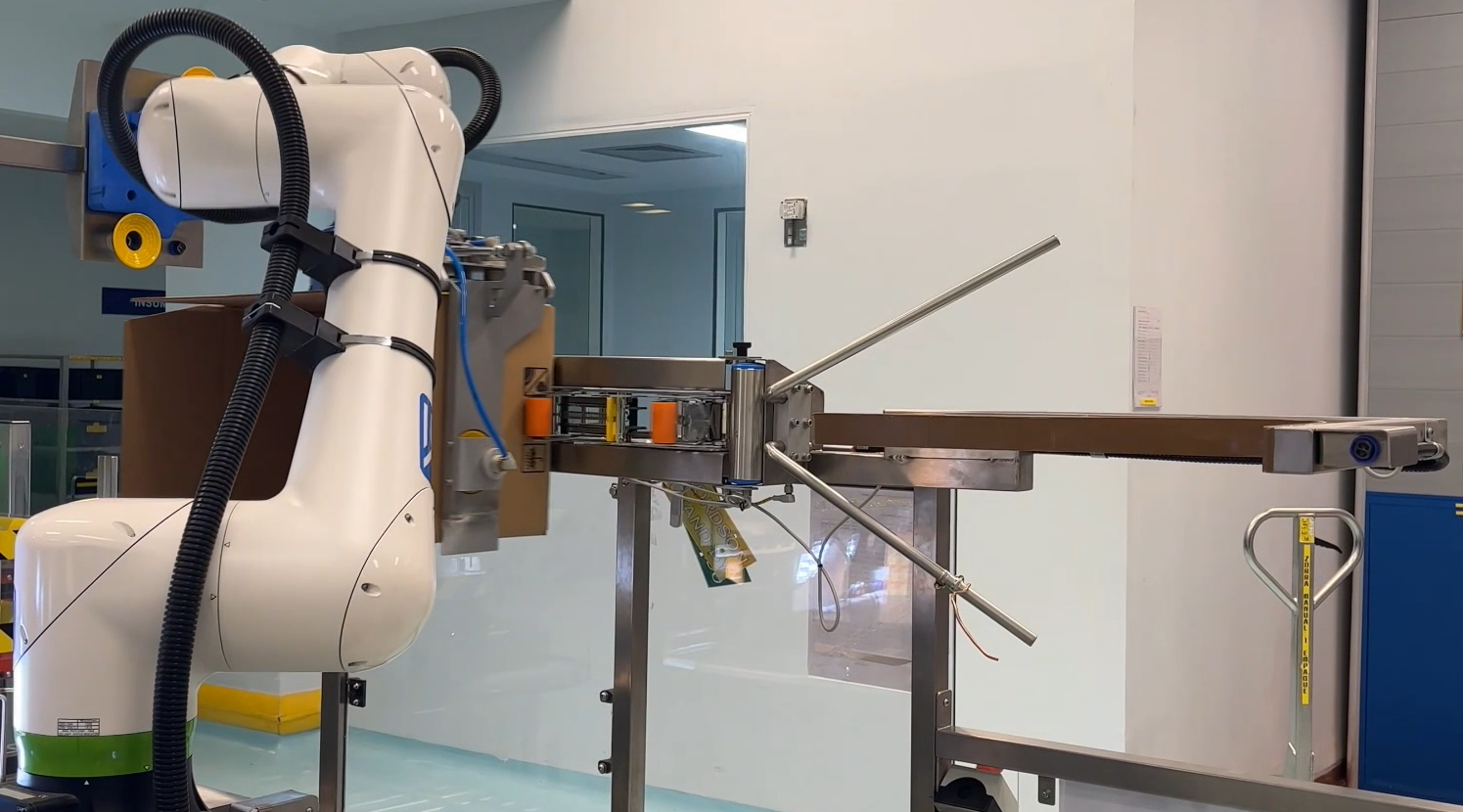

Automates the loading and unloading of sheet metal blanks into presses, ensuring consistent positioning, reduced handling risk, and stable cycle times across stamping operations.

Enables precise and synchronized transfer of parts between consecutive presses in single or tandem press lines, improving throughput and process consistency.

Automates removal of formed components from the press and stacks parts systematically, supporting downstream processes while maintaining part orientation and quality.

Facilitates safe and controlled removal of scrap material from press operations, helping maintain a clean press shop environment and uninterrupted production flow.