Forging & Casting Automation

Robotic Automation for High-Temperature Metal Forming Operations

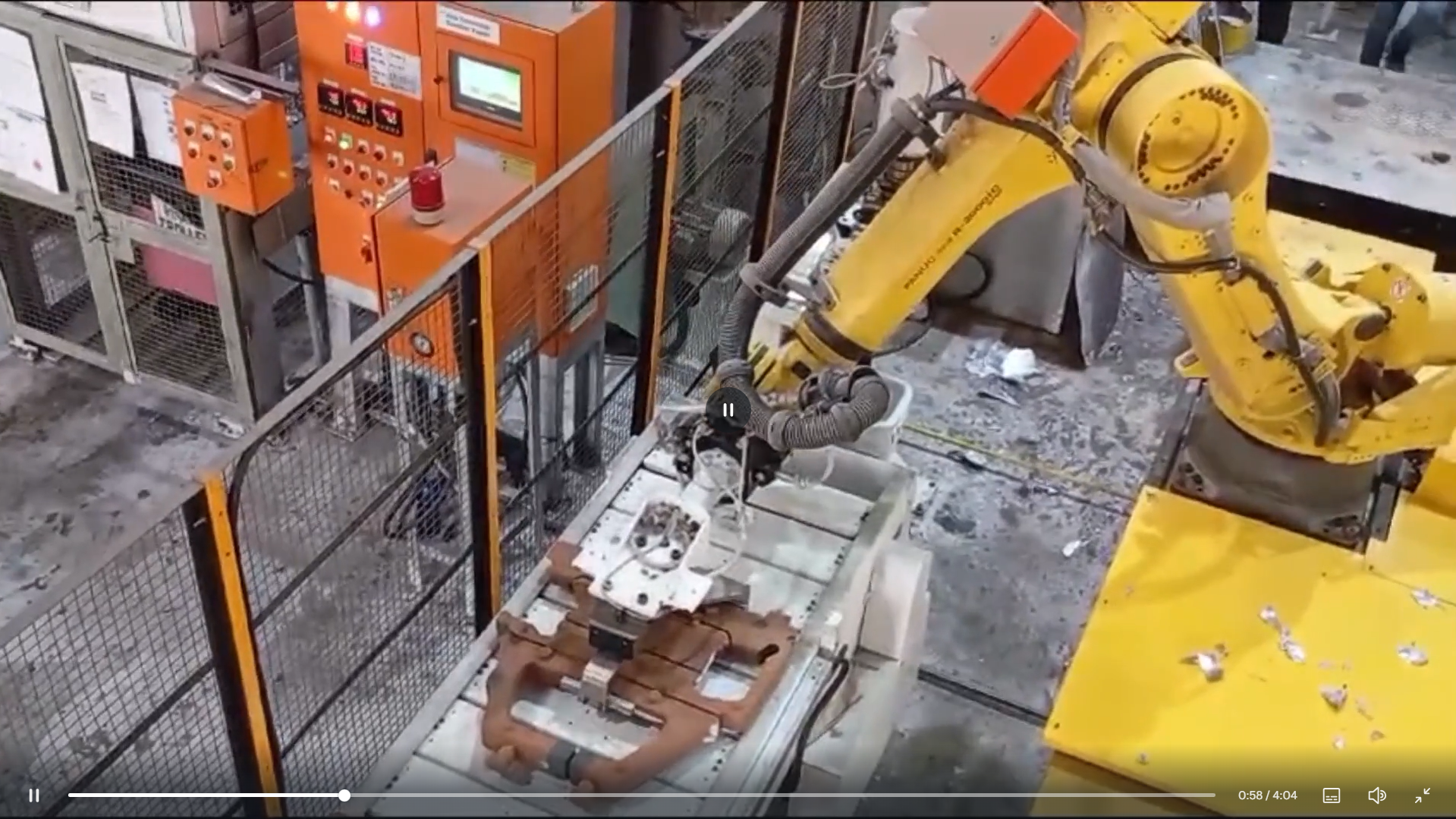

IRTI Robotics delivers end-to-end forging and casting automation solutions by integrating industrial robots, automated material handling, press tending, furnace loading, and inline inspection systems. Our system-integrated automation improves productivity, ensures operator safety, and delivers consistent quality in high-temperature metal forming environments. Designed for automotive, aerospace, heavy engineering, and defense industries, our solutions reduce cycle times, minimize defects, and enable reliable, continuous production.

Forging & Casting Automation Overview

Forging and casting automation integrates industrial robots, automated material handling systems, and advanced control technologies to optimize high-temperature metal forming operations. These solutions automate critical processes such as billet and molten metal handling, furnace loading, press tending, die positioning, trimming, and finishing. By eliminating manual intervention in hazardous environments, automated forging and casting systems deliver higher precision, improved cycle consistency, and enhanced operator safety.

As a system integrator, IRTI Robotics designs and deploys end-to-end forging and casting automation solutions that improve productivity, reduce defects, and ensure repeatable quality. Inline inspection, real-time process monitoring, and AI-driven vision systems enable dimensional accuracy, defect detection, and process optimization. Widely adopted across automotive, aerospace, heavy engineering, and defense sectors, these automation solutions support scalable, reliable, and energy-efficient high-volume production.

Key Benefits of Forging & Casting Automation

- Delivers consistent, high-precision forging and casting across all metal components

- Increases throughput by reducing cycle times and enabling continuous production

- Eliminates manual handling errors, improving overall product quality and repeatability

- Enhances operator safety by automating hot metal transfer and heavy component handling

- Reduces material waste, rework, and energy losses through controlled automation

- Enables real-time process monitoring and predictive maintenance for higher uptime

- Supports open-die forging, closed-die forging, die casting, and hybrid forming processes

- Improves dimensional accuracy and surface finish through repeatable robotic operations

- Integrates AI-powered vision inspection for inline defect detection and quality assurance

- Scales seamlessly for high-volume and high-mix forging and casting production lines

Integrated Forging & Casting Automation Technologies

Robust forging and casting automation systems engineered to improve process precision, operator safety, and production efficiency across high-temperature and high-load metal forming operations.

Automated Molten Metal Pouring

Robotic molten metal handling and pouring systems that ensure accurate dosing, controlled flow, and repeatable casting quality while minimizing operator exposure to extreme heat.

Robotic Sand Core Handling

Automated sand core loading, positioning, and removal using industrial robots to improve dimensional accuracy, reduce core damage, and maintain consistent mold integrity.

Automated Die Loading & Unloading

High-payload robotic die handling solutions enabling fast, repeatable die changeovers, reduced downtime, and improved forging and casting cycle efficiency.